Mpression OtoSense Smart Motor Sensor

Do you have any of these troubles in your production process?

Sudden motor failure!

No spare

Downtime occurs!

Due to motor failure

valuable material

to discard...

I want to expand my production facilities

but lack of staff

Worried about maintenance...

Smart Motor Sensor(SMS) for these industrial

Food

Beverage

Pharmaceuticals and cosmetics

Papermaking/printing

Semiconductors/electronics

Plant equipment

Overview: More than just a sensor

ADI OtoSense Smart Motor Sensor (SMS) monitors the condition of your electric motors by combining best-in-class sensing technologies with leading-edge data analysis. ADI OtoSense SMS detects anomalies and defects in equipment, enabling you to forecast maintenance cycles and avoid unplanned downtime.

Agnostic of motor type, ADI OtoSense SMS covers the most critical diagnostics, translating data into actionable insights. The Smart Motor Sensor allows for 24/7 condition-based monitoring of all your low voltage electric motors. It presents information in a clear way, telling you both what the problem is and how to fix it.

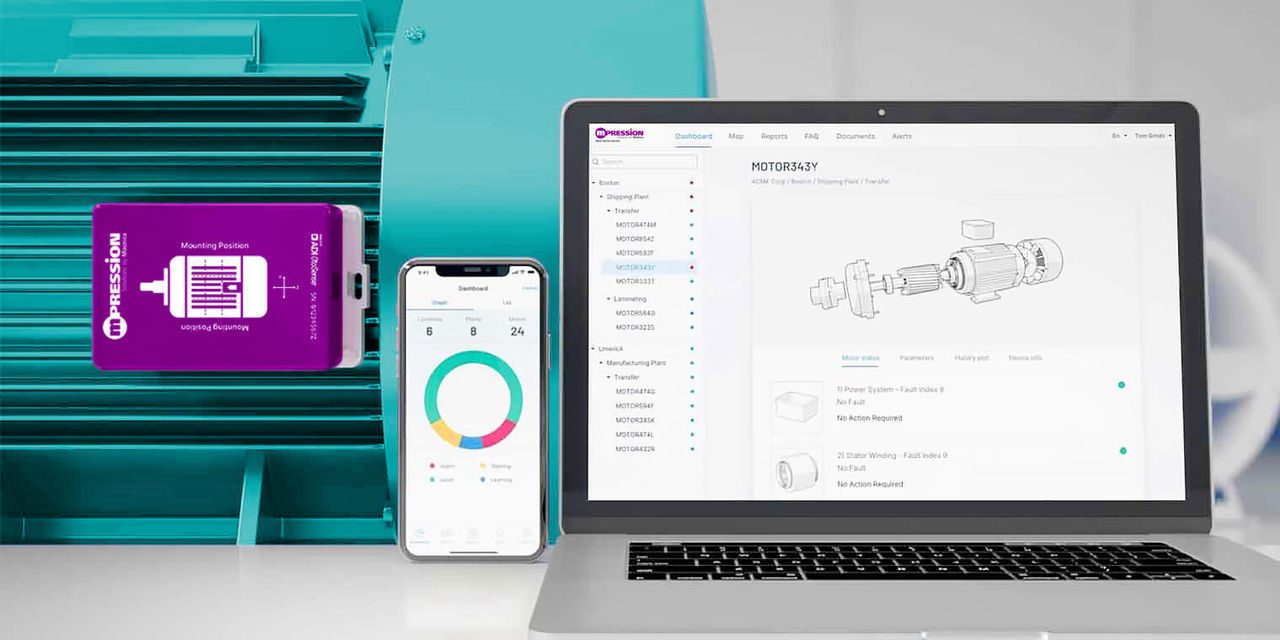

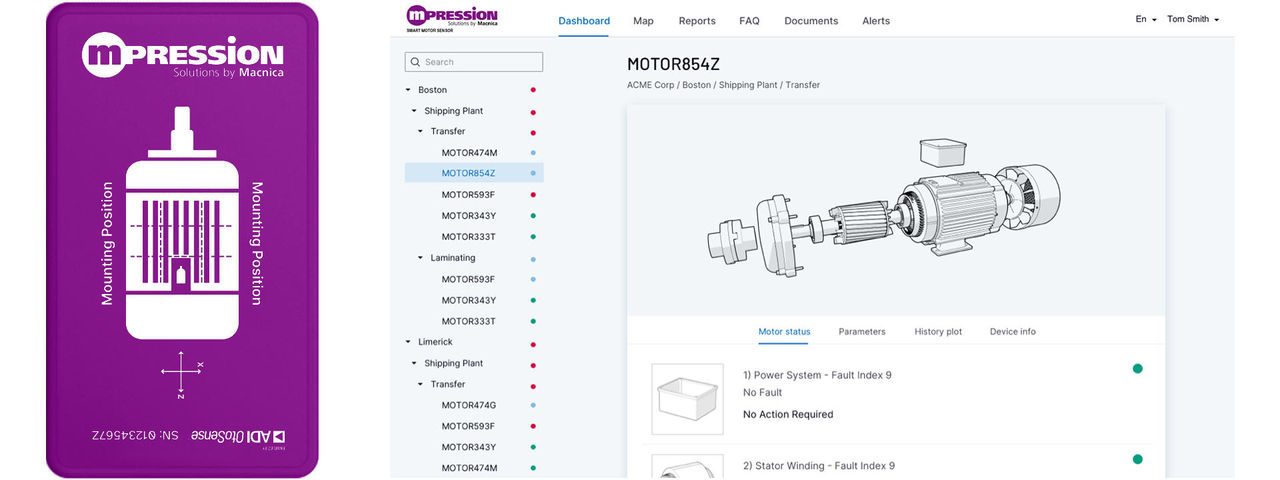

Mobile Application

The ADI OtoSense SMS App allows easy setup of your Smart Motor Sensors, visibility on deployment data, and in-app notifications and alerts on critical events.

Dashboard

Get a complete overview of your machine health diagnosis and fault detection with detailed information and visualization of each motor's status.

Three features of smart motor sensors

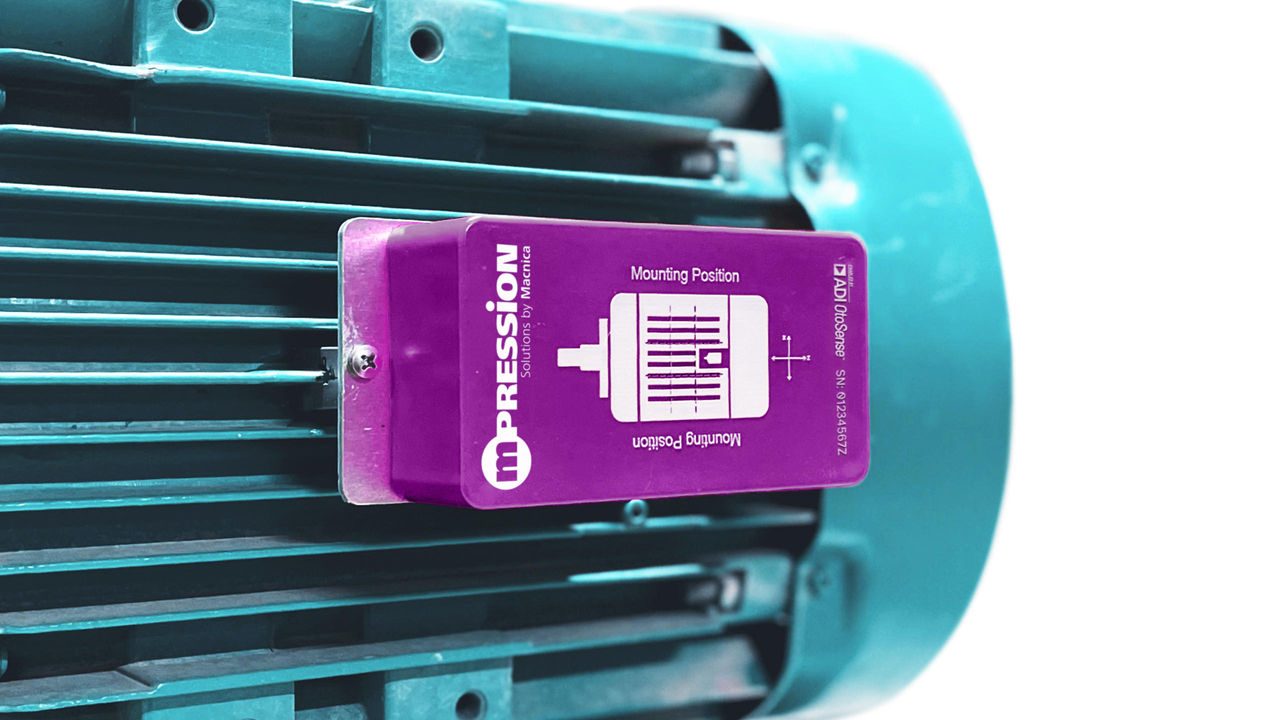

Easy installation

Battery powered (4 AA batteries)

Wi-Fi compatible, no wiring required

No expertise required

Start learning and diagnosis automatically

Immediate alarm notification for abnormalities

Nine abnormal modes

Equipped with 9 motor-specific failure modes

Notification of specific points and countermeasures

Benefits—Rethink your predictive maintenance strategy

ADI OtoSense SMS optimizes your production environment and reduces breakdowns using robust condition-based monitoring hardware and software. Realize benefits such as lowering asset maintenance costs, extending equipment life, and increasing uptime.

Monitor in realtime

Monitor your equipment more frenquently to know when mechanical and electrical failures start to occur and how these issues impact your production process.

Take action

A unique model is created for each motor to deliver optimized diagnostics that align with the process. The Smart Motor Sensor provides information you can use to not only diagnose the problem but know the severity so maintenance teams can take action.

Optimize business

By continuously monitoring your motor performance and health, you will have better visibility into maintenance and spare parts needs to know what to order and when to order, reducing inventory costs.

Identified fault types

ADI OtoSense Smart Motor Sensor (SMS) is the most accurate solution on the market to sense and interpret your machine data. This is why we define ourselves as a sensing interpretration world leader. The SMS can detect the following failures:

Power System:

Asymmetry in motor currents

Faults caused in the motor power system that can cause an asymmetry in the motor currents. For example, loss of a phase or change in the impedance of power cables.

Motor shaft/Balance:

Gracity center displacement

Machine rotor unbalance as a consequence of the gravity center displacement of any of the motor rotating parts. For example, accumulation of dust on the motor fan, loss of balance parts of the rotor, mismatch of the coupling plate, flexed shaft.

Alignment:

Motor/load misaligned

Loss of alignment between motor and motor load.

Stator winding:

Stator resistance variation

Faults caused in the motor stator, may cause an asymmetry in the motor currents. For example, variation of the impedance of one of the motor phases.

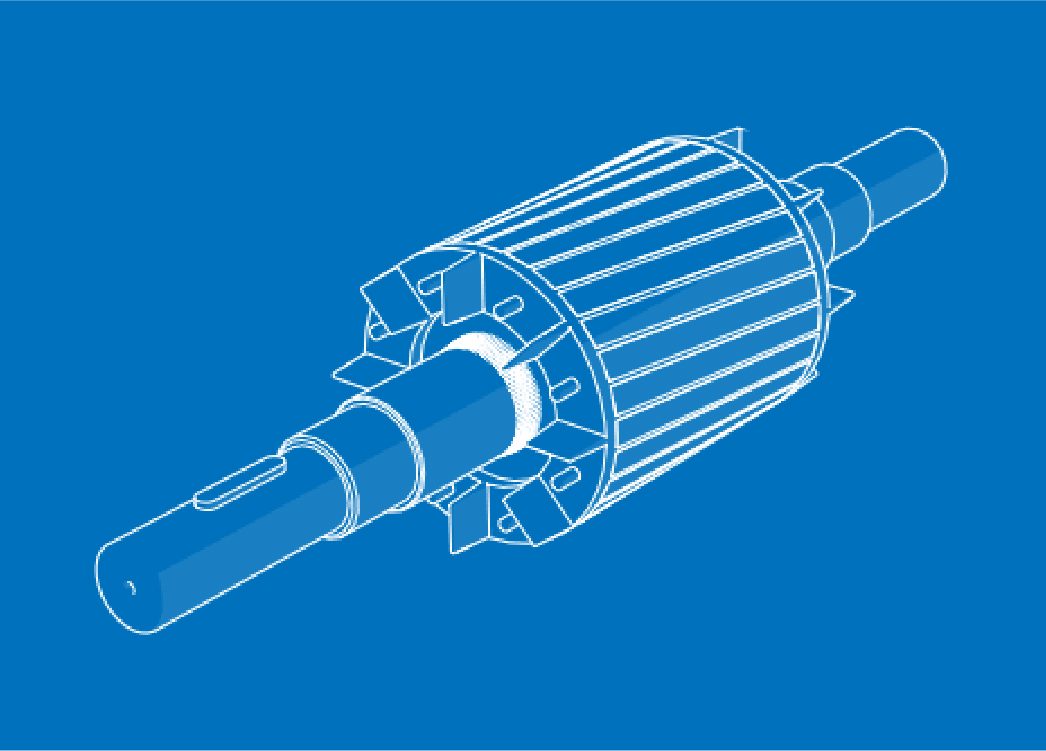

Eccentricity:

Stator/rotor concentricity issue

Malfunction of the motor when the concentricity between the stator and the rotor is not maintained. The reasons can be a bent rotor shaft on large machines or a tilted shaft as a result of poor bearing installation.

Cooling System:

Motor cooling system problem

Problems in the motor cooling system, such as obstruction of the ventilation outlet or the fan stop, in case of independent ventilation of the motor.

Rotor:

Rotor resistance variation

Rotor failures such as discontinuities in the active part of the rotor, such as rotor bars or short-circuit ring, or problems in the welds of the copper rotor. These problems usually occur in motors that start and stop very frequently and with high loads.

Bearing:

Failtures/defects in bearing

Bearing failures such as lack of lubrication or defects in the inner and outer race, the cages or the rolling elements. The reasons for the origin of these failures can be: lack of maintenance of the bearing, poor installation of the bearing, unsuitable operating conditions, electrical currents in the bearings.

Soft/Loose foot:

Fixing system problems

Problems in the fixing system of the motor to the operating bench.

Performance

This performance indicator identifies potential systemic issues that are indicative of a load problem or process change that might require further action on the system and manufacturing process.

Specifications and requirements

The Smart Motor Sensor (SMS) works with:

- 3-phase squirrel cage induction motor.

- Standard low voltage IEC and NEMA motors.

- Frames up to 450 (IEC 60034) or 500 (NEMA MG1) whose power range varies from 0.37 kW to 500 kW or from 0.5 hp to 700 hp.

- Motors driven by any type of device (directly on line (DOL)), by variable frequency drive (VFD), soft starter, and star-delta.

Physical characteristics

- Weight: 0.5 kg

- Case material: ABS

- Mounting: Cooling fins

- Battery type: 4 × replaceable AA lithium batteries

Vibration measurement

- Amplitude range: ±40 g

- Frequency range: 1 Hz to 3.1 kHz

- Data format: Waveform, FFT, rms

- 2-axis vibration: Axial and radial

Wireless communication

- Network standard: Wi-Fi b/g/n

- Radio standard: IEEE 802.11 b/g/n

- Frequency: 2.4 GHz

- Range (nominal): >50 m