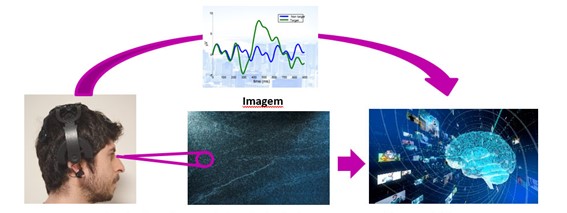

Discover the solution used to label images through neural signals and train the AI network

InnerEye is a BrainTech company from Israel (partner of the Macnica Group Inc.) that combines Artificial Intelligence (AI) with human intelligence through the capture and interpretation of brain waves.

The human brain performs a series of neural activities to identify an image, such as: seeing an object, recognizing this object and making a decision.

With this technology, it is possible to quickly implement image recognition systems, which teach and train a machine to classify data.

Brain Waves

How does InnerEye's solution work?

The InnerEye headset speeds up the process of identifying images and inserting labels. This happens automatically from the moment the image is shown on the monitor and the specialist's EEG (electroencephalogram) brain signals are captured.

When looking at the image, processing activities are automatically initiated in the human brain for evaluation and classification. The neurons involved generate and distribute electrical signals.

These signals can be digitalized without invasive techniques on the scalp surface and transmitted to computer units for evaluation.

By capturing brain waves, InnerEye's solution can identify the judgment and classification of an image observed by a person, allowing the image to be automatically and immediately labelled.

InnerEye's solution displays images on a screen to specialists in quick succession and determines a key figure from the captured EEG signals.

With this method, AI algorithms can be trained very quickly and loaded with the experts’ knowledge. In this way, the transfer of experience from person to machine occurs efficiently.

In addition, EEG patterns can also be used to show concentration, fatigue or distraction and thereby evaluate the results with a factor of safety.

Case 01

In Brazil, researchers from the Brazilian Agricultural Research Corporation (Embrapa), created in 1973 by the Brazilian Government to develop the technological basis for a genuinely tropical model of agriculture and livestock, are already using this technology.

Embrapa researchers' neural signals are being used to identify diseased plants.

According to the phytopathologist researcher Cláudia Godoy, who participated in the tests, the result was surprising, as it identified with high accuracy the photos with diseased and healthy leaves, reading only the neural signals with the InnerEye collector headset.

The project consists of labelling the photos of soybean leaves, using the neural signals of the Embrapa Soja researchers.

According to Embrapa researchers, identifying phytopathological diseases at an early stage is crucial to have the best treatment and result.

To make the identification, the researchers look at the photos on the monitor and the headset collects the neural response of the image, being possible to label 3 photos per second. Currently this process takes an average of 5 to 10 seconds when done manually.

Another important feature of the InnerEye system is to measure the degree of confidence the specialist had in identifying whether the leaf is diseased.

This is extremely important to ensure the accuracy of the system, using the responses of different researchers, with different experiences.

This pioneering initiative by Embrapa will create a system that will help producers to identify diseases at their initial levels with high reliability.

Case 02

Intel and Macnica have developed a series of solutions to reduce costs and bring greater performance to Ambev, which is part of the Anheuser-Busch InBev group, the largest beer manufacturer in the world and the 14th largest company in Brazil in this segment. AMBEV controls about 69% of the Brazilian beer market.

With artificial intelligence (AI), the analysis of images of the brewery's vehicles, which was previously done manually, now occurs 18 times faster thanks to Intel's OpenVino™ technology - an opensource platform for optimizing the performance of neural networks inference, and the Macnica's InnerEye solution, which identifies the judgment and classification of an image through brainwave capture.

Within Ambev's distribution operation, one of the necessary activities is to inspect the visual condition of the vehicles responsible for delivering products.

This inspection is carried out through images sent by couriers periodically, which are analyzed by a Company technician who classifies these images as approved or not, if the vehicle is not in visual conditions consistent with the brand.

Currently, around 10,000 images are received per month for evaluation, with the technician taking 2 to 10 seconds to analyze each image (about 4 business days), plus the time it takes to record the results, classify them and notify the deliverers.

To reduce this time, Intel and Macnica, supported by BeerGarage and Log.Co, presented InnerEye's solution that allows the image to be automatically and immediately labelled, as explained by the director of technology solutions division at Macnica ATD Europe, Fábio Petrassem de Sousa. “This solution combines the direct intelligence of the human brain with AI technology. With this, it is possible to create more accurate classifications, such as identifying images or patterns in X-rays, from the neural signals of a doctor”.

To achieve maximum performance and make the best possible use of the selected hardware, the Intel® Distribution of OpenVINO™ toolkit was also used.

The platform improves deep learning inference performance in computer vision, speech recognition, and natural language processing topologies.

“Regardless of the type and size of a brewery or any other establishment, such as a Distribution Center, we are talking about several points where we can apply Computer Vision and OpenVino can support a lot, for example: Production processes, control processes quality control processes, water treatment control processes, employee safety processes, asset location and identification processes”, highlights Igor Freitas, AI specialist at Intel Brazil.

The use of the camera in these cases is very positive and fast. You have a certain indicator to be monitored, it simply needs to be pointed at the desired location, connected to the network and the rest of the work is done by the AI algorithms to : classify, locate, measure, recognize or segment something.

“Solutions like this are improving and making truck image analysis processes more efficient, removing the need for a human being to perform this task, saving time and gaining efficiency. The applicability of this technology is so comprehensive that, for 3 years to date, BeerGarage and other innovation teams at Ambev have been working on several initiatives using Computer Vision, to solve, monitor, alert different situations that bring harm, poor quality or inefficiency of our processes, be they Logistics, Brewers, Supply Chain, Bars, Restaurants, Supermarkets” says researcher and AI specialist at BeerGarage (Global Innovation Team), Eduardo Dutra.

Contact us to find out how InnerEye's solution can impact your process using Artificial Intelligence.

Email: marketing.mae@macnica.com