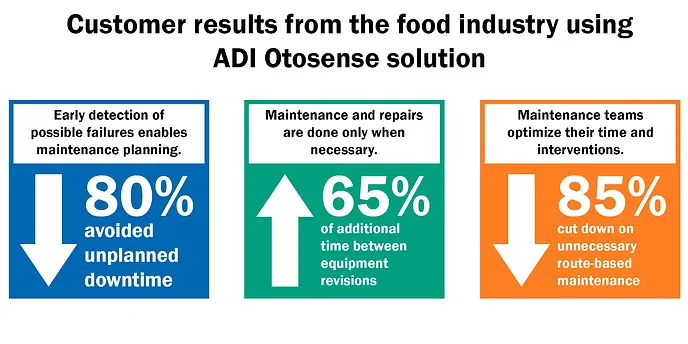

Impacts of the OtoSense solution in the food industry

The production of the food industry cannot stop unexpectedly, as this would result in great losses. Therefore, this market needs to invest in predictive maintenance to avoid a drop in production, loss of raw materials, and increased costs for semi-finished products.

It was this investment that a global food company made using the ADI OtoSense solution. With this hardware and software solution that performs predictive maintenance, the company optimized the production and maintenance process.

Before learning more about this case, let's understand how important this solution is for the food industry.

Why is the ADI OtoSense solution important for the food industry?

ADI OtoSense SMS (Smart Motor Sensor) has a positive impact on food industry production. It constantly monitors the overall health of the motors that drive major food manufacturing equipment such as: centrifugal machines, pumps, mixers, chillers, compressors, etc.

Using its artificial intelligence, the ADI Otosense solution sends warnings and alerts as soon as a sign of wear or failure is identified. In this way, when detected at an early stage, breakdowns and failures can be prevented. In addition, the information provided on the severity level and origin of the failure allows better maintenance planning, avoiding line stoppages or production losses.

Case of the ADI OtoSense solution in the food industry

Challenges of the company

A global food and biochemicals company was looking for a solution to perform real-time monitoring of lactic acid production processes. The reason was that a key piece of equipment - a powerful centrifugal machine - broke down at least once a year due to a design flaw and a bearing lubrication problem.

When this happened, the machine would be down for three weeks, resulting in significant costs:

repair materials, such as crane, labor hours, parts, etc;

high impact on production, which was stopped without the centrifugal machine.

Solution to the problem

Unexpected shutdowns in the food industry can be avoided with real-time monitoring of the equipment and alerts to the person in charge whenever any of them show abnormal behavior. For this, it is necessary to implement predictive maintenance.

With the ADI OtoSense Smart Motor Sensor solution, when the lubrication system is about to fail, an alert is issued to the maintenance team in advance. Thus, the machine can be stopped and maintained before the bearings and main shaft break down.

Due to the good results of using the ADI OtoSense solution, such as accuracy and ease of use, it will be implemented in the other machines of the production line. See below the results of the food industry customer after using this solution:

Want to know how we can help you make the implementation of predictive maintenance in your industry? Contact us at marketing.mae@macnica.com.