ADI OtoSense Smart Motor Sensor for Reliable Maintenance in Energy Plants

Energy production facilities worldwide face a critical challenge: millions of critical, low voltage motors running continuously without adequate health monitoring. This reality creates scenarios where undetected motor degradation can suddenly escalate into catastrophic failures, triggering costly unplanned downtime and potentially disrupting energy production for thousands of consumers.

Modern energy plants typically span massive footprints where extreme environmental conditions, significant temperature fluctuations, and inherently noisy operations create imperfect conditions for traditional motor health assessment. Conventional approaches relying on sound and vibration measurement become practically useless in environments with high ambient noise levels, extreme temperatures, and safety restrictions that limit human access to critical equipment areas.

ADI OtoSense Smart Motor Sensor technology emerges as a purpose-built solution for these monitoring challenges. This comprehensive continuous health monitoring system transforms the traditional reactive maintenance paradigm by providing real-time, actionable insights into motor condition across entire energy plant operations. The system works synergistically with existing domain expertise, amplifying the knowledge and experience of mechanical specialists to create an unprecedented predictive maintenance capability that enhances motor efficiency, improves productivity, and delivers measurable positive impact on profitability.

When Traditional Methods Fail: The Harsh Reality of Energy Plant Motor Monitoring

Modern energy plants present a unique combination of monitoring challenges that traditional maintenance approaches cannot address effectively. The fundamental problem extends beyond technical limitations to encompass practical operational constraints that make comprehensive manual monitoring both dangerous and economically unfeasible.

Energy plant environments create inherently hostile conditions for equipment monitoring activities. Large facilities generate substantial background noise that masks the subtle acoustic signatures indicating developing motor problems. High operating temperatures affect both equipment performance and the accuracy of traditional measurement techniques, while safety protocols necessarily restrict human access to many critical equipment locations. These environmental factors combine to create situations where the very conditions that accelerate equipment wear are also the conditions that make early detection most difficult to achieve.

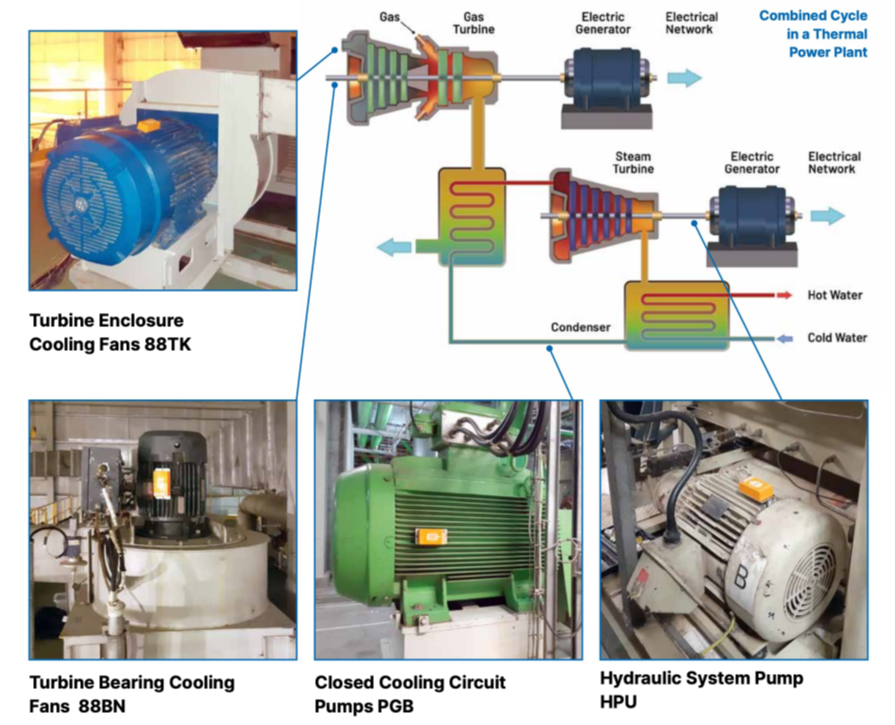

Experienced maintenance technicians represent scarce, valuable resources whose expertise cannot be efficiently deployed through continuous manual inspection across massive plant facilities. The physical impossibility of maintaining continuous human surveillance over every critical motor creates inevitable monitoring gaps, particularly for secondary equipment — cooling water pumps, soot blower mechanisms, gear boxes, vacuum pumps, gas turbine frames, and bearing cooling fans. Unfortunately, These secondary systems possess the same potential to trigger plant-wide shutdowns when experiencing unexpected failures.

Next-Generation Sensing Technology That Thinks and Learns

The ADI OtoSense Smart Motor Sensor addresses energy plant monitoring challenges through an integrated approach, combining cutting-edge sensing hardware with sophisticated analytical software.

Advanced sensing capabilities include :

- Multi-axis, wide bandwidth vibration sensors capturing detailed mechanical signatures

- Integrated magnetic field sensors for continuous electrical health monitoring, detecting insulation degradation and winding problems

- Temperature monitoring systems tracking ambient conditions and motor skin temperatures

The machine learning architecture represents a fundamental advancement in motor monitoring technology. Automated model creation processes eliminate the need for extensive manual configuration while ensuring optimal monitoring performance regardless of motor brand or manufacturer specifications. Learning algorithms analyze operational patterns specific to each motor, creating customized baseline profiles that improve detection accuracy and reduce false alarms.

Areas of Use in Engery Plants (combined cycle)

Wireless and gateway-free, the Smart Motor Sensor offers fast, low-cost deployment and reliable operation in harsh energy plants. Sampling at 6.2 kHz every 20 minutes ensures broad fault coverage with minimal data load.

Diagnostic capabilities extend beyond simple fault detection to include advanced analytics that prioritize maintenance actions based on severity assessments and operational impact analysis. The system differentiates between electrical and mechanical fault conditions while providing specific recommendations for required maintenance actions.

Quantifiable Results That Drive Operational Excellence

Real-world implementations of ADI OtoSense Smart Motor Sensor technology demonstrate significant operational improvements.

- Downtime Reduction

Organizations typically experience 71% reduction in unplanned downtime through early fault detection and proactive scheduling. This directly addresses expensive operational problems—typical unplanned downtime costs range from $30,000 to $50,000 per hour in industrial settings.

- Maintenance Cost Optimization

Organizations achieve 75% reduction in overall maintenance costs by transitioning from schedule-based to condition-based maintenance strategies. The system enables teams to focus resources on equipment requiring attention rather than following arbitrary schedules.

- Practical Benefits

The Smart Motor Sensor enables efficient monitoring of critical motors including gas turbine cooling fans, hydraulic oil control pumps, and closed-circuit refrigeration pumps. Maintenance Managers report the system eliminates unnecessary preventive work while optimizing manual vibration measurement activities, saving valuable labor hours and preventing operators from accessing dangerous locations.

- Operational Reliability

Extended equipment life, optimized motor efficiency, and improved Overall Equipment Efficiency metrics create additional value. Early problem detection enables corrective actions preventing damage progression. Current industry statistics indicate 80% of organizations lack reliable information about optimal asset replacement timing, while 75% cannot accurately determine appropriate maintenance scheduling—gaps the Smart Motor Sensor addresses through data-driven insights.

Your Gateway to Smarter Energy Operations

The ADI OtoSense Smart Motor Sensor represents a transformative solution that addresses fundamental challenges facing energy plant operators. By providing comprehensive monitoring capabilities specifically designed for harsh energy plant environments, this system enables the transition from reactive maintenance practices to proactive, data-driven operational strategies that enhance both reliability and profitability.

Macnica ATD Europe provides dedicated technical support and implementation expertise to ensure successful Smart Motor Sensor deployment in energy plant environments. Our experienced team combines technical knowledge with practical implementation experience to deliver solutions tailored to specific operational requirements and performance objectives.

Transform your maintenance approach and eliminate costly unexpected failures.