SenSWIR: A New Vision for Quality Control in Food Manufacturing

In today's competitive industrial landscape, undetected contaminants represent a silent yet significant threat. Minute impurities can compromise product quality, endanger public safety, and devastate your brand reputation. Imagine confidently identifying hidden contaminants before they ever pose a risk, ensuring flawless quality control in critical sectors like food processing, pharmaceuticals, and electronics manufacturing.

To meet this challenge, Sony has developed the SenSWIR image sensor, a cutting-edge solution that unlocks a new dimension in vision. With its ability to see beyond the visible spectrum, SenSWIR redefines how industries detect and eliminate invisible threats.

The blind spots of conventional imaging

Traditional image sensors are limited to the visible spectrum, which restricts their ability to reveal what's happening beneath the surface. Water, oils, plastic fragments, and other impurities often go unnoticed when inspected with standard cameras. For industries that depend on purity and consistency, these blind spots come at a high cost: compromised batches, delayed production, and the looming risk of recalls.

Relying solely on conventional imaging is like navigating a dark room with a flashlight, it offers some clarity but leaves critical areas in the shadows. In sectors where precision is non-negotiable, this isn’t just a limitation; it's a liability.

How Sony’s SenSWIR transforms contaminant detection

SenSWIR opens a new window into quality control by capturing images in the short-wave infrared range. This spectral sensitivity allows it to detect materials based on their specific absorption characteristics. Moisture trapped under packaging, oil residues invisible to the naked eye, or plastic particles embedded in powder—SenSWIR reveals what traditional sensors can’t.

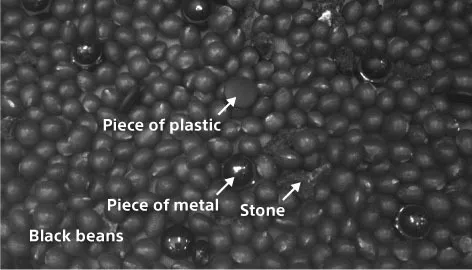

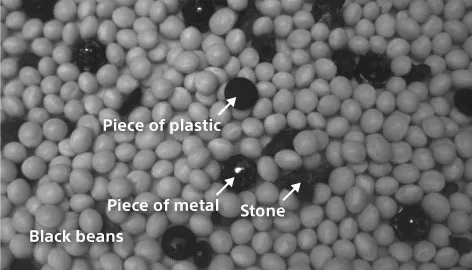

In food manufacturing, for instance, differentiating contaminants that share the same color as the product is a recurring challenge. Using SWIR imaging, what was once visually indistinguishable becomes clearly separated. Imagine a stream of black beans on a conveyor belt—while a black-colored foreign object might blend in under standard inspection, SenSWIR can easily spot the difference by analyzing their distinct reflectance patterns.

Under visible light

Under SWIR (1,300nm)

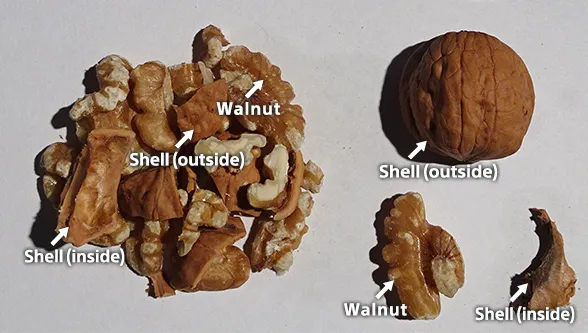

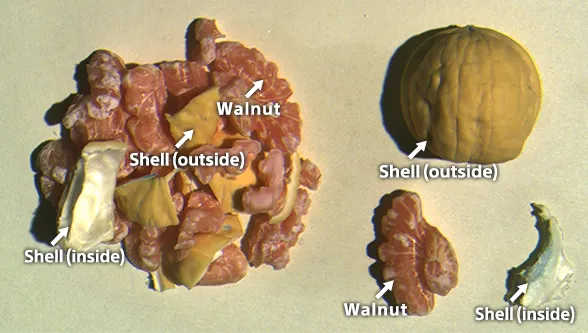

Another compelling case is in the processing of nuts. Walnut shells, often difficult to detect with conventional lighting, become immediately visible through SWIR-based image processing. By combining data from multiple SWIR wavelengths and applying pseudo-color imaging techniques, manufacturers can easily isolate shell fragments from the edible nutmeat, preventing foreign materials from reaching the final product.

Image taken with a standard color camera

Image taken and processed with SWIR

(1,050/1,200/1,450nm)

This advanced level of precision goes beyond image quality. It empowers manufacturers to make more informed decisions, react more swiftly to anomalies, and reduce unexpected issues. With SenSWIR integrated into their operations, they gain deeper visibility into their processes and greater control over product quality.

Achieving more with the right partner

Precision imaging is only as valuable as the results it delivers on the production floor.

With Macnica ATD Europe, you gain a trusted partner who ensures that Sony’s SenSWIR sensor is not only implemented effectively but optimized for your specific environment. Together, we turn visibility into efficiency, reliability and long-term success.

Contact us to unlock new levels of control and insight.