Sony Image Sensors: The Revolution in Industrial Automation with Precision and AI

Sony’s image sensors are synonymous with innovation in industrial automation. Combining high performance, artificial intelligence, and easy integration, these components are transforming the industry.

Why invest in Sony image sensors for industrial automation?

Sony has been recognised for its excellence in image sensors for decades. choosing their image sensors means betting on proven innovation. That’s why their applications in industrial automation ensure exceptional results, offering high resolution with fast and reliable readings. Additionally, they are compact and easy to integrate with existing systems. Thus, by investing in Sony’s image sensors, you reduce adaptation time and almost immediately increase productivity. Moreover, these image sensors are recognized for their versatility, as they adapt to many applications, from visual inspections to smart robotic systems. Therefore, using Sony’s image sensors for industrial automation strongly benefits your company in terms of quality control and performance.

Enhancing Industrial Automation with Sony's Image Sensors

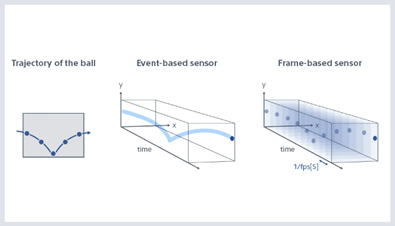

Sony’s image sensors are designed to meet the demands of the modern industry. They use advanced technologies that eliminate distortion in images of fast-moving objects, ensuring precision even in high-speed environments. Logically, this feature is essential for the reliability of inspections and measurements on automated production lines. Additionally, Sony’s image sensors are used in machine vision systems, which are also applied in industrial automation. This integration enables the development of customized solutions for inspection, control, and identification, increasing efficiency and reducing human errors in production processes.

Applications of Sony Image Sensors in Industry

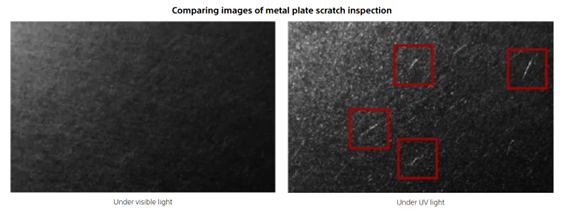

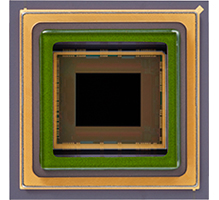

Sony’s image sensors shine in applications that require high precision. For example, in the metal industry, the IMX06A model detects scratches on plates using ultraviolet light.

The IMX06A delivers the highest resolution in a 1” format with 50MP and a rolling shutter design. With its on-chip re-mosaic function, MIPI interface, excellent low noise, and wide dynamic range, it is ideal for visual inspection and industrial applications that demand extreme sensitivity and detail. The IMX530, a flagship back-illuminated global shutter sensor, provides both high resolution and high speed, making it a top choice for industrial automation and precision inspection tasks. For even broader capability, the IMX992 brings the industry’s smallest pixel size and highest resolution among SWIR image sensors. By combining visible and SWIR imaging in one device, it enables high quantum efficiency from 0.4 μm to 1.7 μm, giving production lines new levels of accuracy in detecting features invisible to the human eye.

That makes the IMX992 perfect for detecting fast-moving objects, equipment monitoring, motion detection analysis, and accurate image recognition. Furthermore, its energy consumption is extremely low.

Examples of Sony’s Image Sensors to help you achieve better productivity

Sony offers a wide range of image sensors, each with specific features to meet the diverse needs of the industry.

Here are some components for you to explore:

Sony IMX06A

The Sony IMX06A is a 50MP rolling shutter CMOS sensor, the highest resolution available in a 1-inch format. With an on-chip re-mosaic function and MIPI interface, it delivers extremely high sensitivity, wide dynamic range, and excellent low noise performance. These capabilities make it ideal for visual inspection and industrial applications where both fine detail and stability are critical.

Sony IMX530

The Sony IMX530 is a flagship back-illuminated global shutter sensor that combines high resolution with high-speed performance. It is designed to deliver distortion-free imaging even when capturing fast-moving objects, excelling in demanding industrial automation and precision inspection tasks where accuracy and reliability cannot be compromised.

Sony IMX992

The Sony IMX992 is a short-wave infrared (SWIR) image sensor with the industry’s smallest pixel size and highest resolution in its class. It uniquely combines visible and SWIR imaging in a single sensor, with high quantum efficiency from 0.4 μm to 1.7 μm. This dual-spectrum capability allows production lines and inspection systems to detect features invisible to the human eye, opening new possibilities for quality control, material sorting, and defect detection.

Are you looking to increase your productivity with Sony’s image sensors? Contact Macnica!

Each of Sony’s image sensors guarantees efficiency, speed, quality, and precision, and they all come with precise documentation and specialized technical support from Macnica. Integrating these technologies into your system is easier than it seems, and Macnica can assist you at every step, from selection to implementation.

Contact us and discover how Sony’s technology can revolutionize your industrial process.